Tailored Noise Enclosures for Industrial and Commercial Noise Control

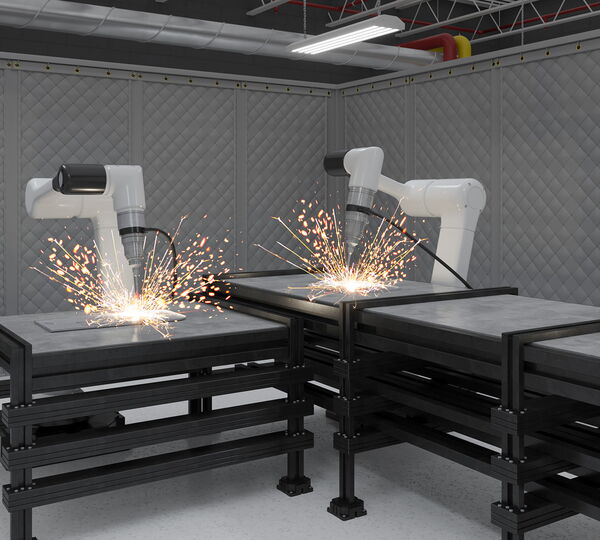

Acoustic noise enclosures are specially designed structures that surround a noise source to contain and significantly reduce the sound it produces into an environment. By creating a physical barrier made of sound-absorbing and sound-blocking materials, enclosures help to isolate noise and prevent it from spreading into surrounding environments.

Noise enclosures typically consist of panels or walls made from sound-insulating materials. For moderate noise reduction (up to approximately 25 dB), curtain panel enclosures—constructed with composite sound barrier and absorber materials—are commonly used. These flexible systems offer quick installation, easy access, and cost-effective performance for many industrial applications.

For higher noise reduction requirements (greater than 25 dB), rigid metal enclosures are employed. These systems utilize heavy-duty sheet metal walls, often lined with absorptive insulation and fitted with access points, ventilation, and observation features. Metal enclosures are highly effective for containing very loud equipment and for applications where structural integrity, durability, and enhanced acoustic performance are essential.

Key Benefits of Acoustic Noise Enclosures

One of the main benefits of acoustic noise enclosures is the ability to contain and significantly reduce noise at the source. Instead of treating an entire room or facility, enclosures target the specific equipment or area generating the noise, offering an efficient and localized solution.

Noise enclosures improve workplace safety by reducing the risk of hearing damage and minimizing distractions. Lower noise levels can lead to increased worker productivity, better communication, and improved overall morale. Additionally, acoustic enclosures help organizations comply with OSHA regulations, local ordinances, and environmental noise standards.

Another advantage is the high level of customization available. Enclosures can be designed with removable panels, hinged or sliding doors, viewing windows, ventilation systems, electrical cutouts, lighting, and cable pass-throughs. These features ensure that access, equipment monitoring, and maintenance can occur without compromising noise control performance.

Durability is another key benefit. Metal enclosures offer long-term resistance to weather, impact, and corrosion, making them ideal for outdoor or heavy-duty industrial applications.

Customization Options

At DDS Acoustical Specialties, every acoustic enclosure is designed to meet the specific operational, spatial, and acoustic requirements of the project. Custom options include:

- Access Doors: Single or double doors with sound seals

- Viewing Windows: Laminated or acrylic windows for visual monitoring

- Ventilation: Acoustically treated air intakes and exhaust systems

- Electrical Penetrations: Cable pass-throughs, outlets, and lighting integrations

- Removable Panels: For easy equipment access and serviceability

- Modular Designs: Expandable and reconfigurable systems

- Exterior Finishes: Powder coating, galvanization, and weather-resistant options for outdoor use

We work closely with clients, contractors, and facility managers to ensure that each enclosure fits seamlessly into the operational workflow while delivering superior noise reduction.

Types of Enclosures

Curtain Panel Enclosures

- Flexible panels typically barrier backed or barrier septum composite panels

- Customizable size and features

- STC rating: Up to 33

- NRC rating: Up to .75

- Fire Rating: Class A per ASTM E-84

- Mounting: Suspended, Floor, or Ceiling

- Standard Colors - Black, Tan, Gray, Off-white

- Designer Colors Available

Portable Curtain Panel Enclosures

- Flexible panels typically barrier backed or barrier septum composite panels

- STC rating: Up to 33

- NRC rating: Up to .75

- Fire Rating: Class A per ASTM E-84

- Mounting: Floor on Casters

- Standard Colors - Black, Tan, Gray, Off-white

- Designer Colors Available

Metal Enclosures

- Perforated metal panels for highest noise reduction

- Used in interior or exterior application where 25db+ reduction is needed

- Customizable size and features

- STC rating: Up to 60

- NRC rating: Up to 1.04

- Fire Rating: Class A per ASTM E-84

- Handles tough environmental conditions

- Primed for Paint or Powder Coated

Frequently Asked Questions

A: An acoustic noise enclosure is a specially designed structure engineered to isolate and significantly reduce sound emissions from noisy machinery, mechanical equipment, or industrial processes. These enclosures work by surrounding the noise source with materials that absorb, block, and dampen sound energy, resulting in a quieter environment for workers and the surrounding community. In addition to reducing operational noise, acoustic enclosures can also improve the longevity of machinery by shielding it from environmental elements.

A: Noise enclosures are built using a strategic combination of sound-blocking and sound-absorbing materials to achieve maximum acoustic performance. Common materials include heavy-duty sheet metal for structural integrity, mass loaded vinyl for flexible noise barriers, perforated metal for airflow management, and fiberglass or mineral wool insulation for superior sound absorption. Advanced designs may also incorporate acoustic foams, vibration-isolating mounts, and weatherproof coatings to extend durability, especially for outdoor or industrial applications.

A: The level of noise reduction achieved depends on the design and construction of the enclosure. Curtain panel enclosures, which use flexible composite materials, typically achieve reductions of up to 25dB. For projects requiring more substantial noise control—such as those involving heavy industrial machinery or outdoor generators—rigid metal enclosures are used and can provide noise reductions exceeding 25db+, depending on thickness, insulation type, and sealing quality.

A: Absolutely. Acoustic enclosures are highly customizable to accommodate specific operational needs and space constraints. Customization options include various door styles (swinging, sliding, or removable), large viewing windows for easy monitoring, integrated ventilation systems with acoustic louvers, cable pass-throughs, internal lighting, and modular panel construction for quick assembly or future expansion. DDS Acoustical Specialties designs every enclosure to match the client's equipment, access requirements, maintenance routines, and acoustic performance goals.

A: A wide variety of industries benefit from acoustic noise enclosures. Manufacturing plants use them to contain noise from presses, conveyors, and CNC machines. Power generation facilities install them around turbines and standby generators. Construction projects deploy temporary enclosures for pumps and generators. Water treatment facilities enclose blowers and pumps to minimize community impact. Healthcare, research labs, data centers, and educational institutions also rely on enclosures to maintain low noise levels critical to performance, comfort, and regulatory compliance.

A: Not when properly designed. Effective acoustic enclosures include engineered ventilation systems that allow necessary airflow for cooling without compromising noise reduction. These systems often incorporate acoustic baffles, silencers, or louvered vents lined with sound-absorbing materials. Proper ventilation is carefully balanced with thermal management needs to prevent overheating and maintain equipment performance while still providing robust acoustic attenuation.

A: Installation depends on the type and size of the enclosure. Metal enclosures typically involve assembling modular panels onsite and anchoring them securely to concrete pads, steel frames, or building structures. Curtain-style enclosures may be suspended from ceiling-mounted frames or mounted on free-standing structures. In all cases, installation aims to ensure airtight seals, secure panel connections, and properly integrated ventilation components to maximize acoustic effectiveness.