Economical Ceiling Baffles for Industrial Environments

Industrial sound baffles are vertically suspended acoustical panels designed to absorb sound energy and reduce echo and reverberation in open spaces. Unlike wall-mounted panels that treat flat surfaces, baffles are hung from the ceiling, where they interrupt and trap sound waves bouncing between hard surfaces. This reduces overall noise buildup and improves speech clarity and acoustic comfort.

Baffles are typically made with an absorptive fiberglass or foam core wrapped in a durable facing such as vinyl, fabric, or specialty film. They are lightweight, easy to install, and available in a variety of sizes, colors, and configurations to meet both performance needs and regulatory requirements. Because they treat noise at the ceiling level without taking up floor or wall space, they are ideal for busy, high-traffic facilities.

Key Benefits of Hanging Industrial Baffles

One of the biggest advantages of ceiling-hung sound baffles is their ability to reduce reverberation time in large spaces. Excessive reverberation—when sound bounces and lingers after the source stops—leads to higher overall noise levels and poor speech intelligibility. By suspending baffles throughout the ceiling, these reflective pathways are disrupted, resulting in cleaner, quieter acoustics.

Industrial baffles are also highly economical. They provide a significant improvement in acoustic performance for a relatively low material and installation cost, especially compared to full-scale architectural modifications or enclosure systems. Their modular nature allows for strategic placement based on acoustic modeling and site conditions, maximizing performance with minimal investment.

Durability is another key feature. Our baffles are designed for the rigors of industrial environments, with reinforced edges and cleanable, impact-resistant finishes. We offer options that meet USDA and FDA requirements for use in food processing and hygienic environments, and all baffles are Class A fire rated to meet local building codes and safety standards.

Where to Use Industrial Sound Baffles

These baffles are ideal for use in any large facility with high ceilings, hard surfaces, and excessive reverberation. Common installation areas include:

- Manufacturing Facilities: Reduce noise from machinery and improve communication between workers.

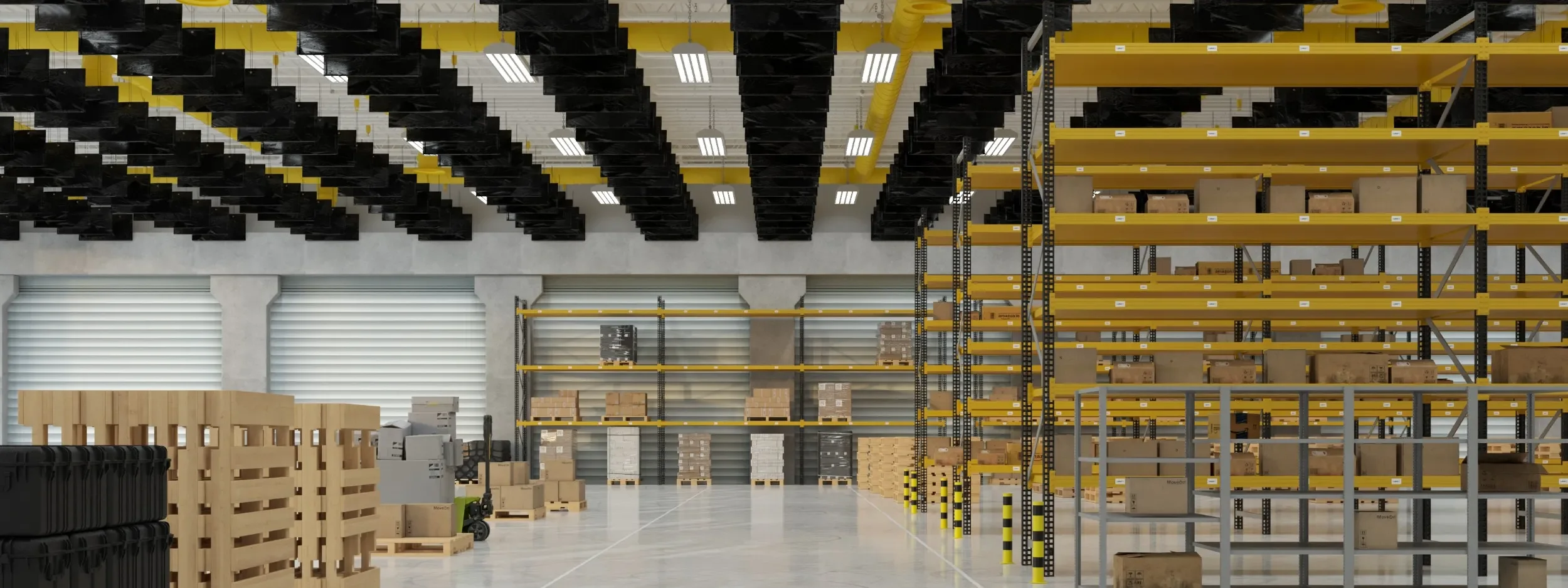

- Warehouses and Fulfillment Centers: Control sound levels in large, echo-prone environments.

- Food and Beverage Plants: Use FDA-approved options for hygienic acoustic control.

- Gymnasiums and Recreation Centers: Improve acoustics for events, sports, and public gatherings.

- Aircraft Hangars and Maintenance Bays: Maintain acoustic comfort without obstructing operations.

Frequently Asked Questions

A: Industrial sound baffles are most effective in large, open environments with hard, reflective surfaces such as concrete, metal, or cinderblock. These include factories, distribution centers, gyms, and hangars where sound waves have room to travel and echo. In these spaces, baffles help reduce excessive reverberation that can drown out conversation, interfere with safety signals, or fatigue workers over long periods. They are particularly useful in areas where traditional wall or ceiling treatments aren’t feasible, making them an ideal solution for overhead noise absorption.

A: Baffles are typically installed by suspending them from structural elements like ceiling joists, open web steel joists, or roof trusses using suspension cables, chains, or mounting clips. Installation configurations can vary depending on acoustic objectives—linear rows work well for uniform sound absorption, while staggered or checkerboard patterns improve diffusion. Lightweight construction makes handling easy, and most installations can be completed without disrupting operations below. Installation hardware is often included, and we provide layout support to ensure optimal placement.

A: Ceiling-hung baffles are not designed to block sound but to reduce reflected sound and reverberation. Depending on coverage, spacing, and ceiling height, they can help lower overall ambient noise levels by 5 to 10 dB or more. The real benefit lies in improving speech intelligibility, reducing echo, and creating a more acoustically balanced environment. With targeted placement, even small quantities of baffles can provide noticeable improvements in areas where clarity and concentration are critical.

A: Industrial sound baffles are manufactured with sound-absorbing cores—typically fiberglass or open-cell foam—wrapped in durable, cleanable surfaces such as PVC-coated fabric, vinyl-laminated polyester, or specialty films. Internal framing or edge reinforcement may be added for rigidity and resistance to sagging. Some baffles feature grommets or D-rings for secure suspension. Materials are chosen for performance, compliance with safety standards, and suitability for the environment they’re used in, including temperature, humidity, and hygiene requirements.

A: Yes. All of our industrial baffles meet or exceed Class A fire rating standards for flame spread and smoke development. This rating ensures that the materials comply with national and local fire codes for use in commercial, industrial, and institutional settings. Fire-rated baffles provide peace of mind in environments where safety is paramount, especially in facilities with overhead lighting, electrical conduits, or other heat-generating elements near the ceiling.

A: Absolutely. We provide FDA/USDA-compliant acoustic baffles designed for use in sanitary or clean processing areas. These baffles feature smooth, non-porous surfaces that resist moisture, are easy to clean, and withstand frequent washdowns. They can be installed in meatpacking plants, bottling lines, commercial kitchens, or pharmaceutical production facilities where cleanliness and compliance are essential.

A: The number of baffles required depends on various factors including the room’s volume, ceiling height, surface materials, and existing acoustic conditions. We evaluate reverberation time, desired sound quality, and noise reduction goals. As a general rule, larger rooms with longer reverberation times require greater baffle coverage, but the final layout can be adjusted for cost-effectiveness and targeted performance.