- DDS Acoustical Specialties

- Applications

- Industrial

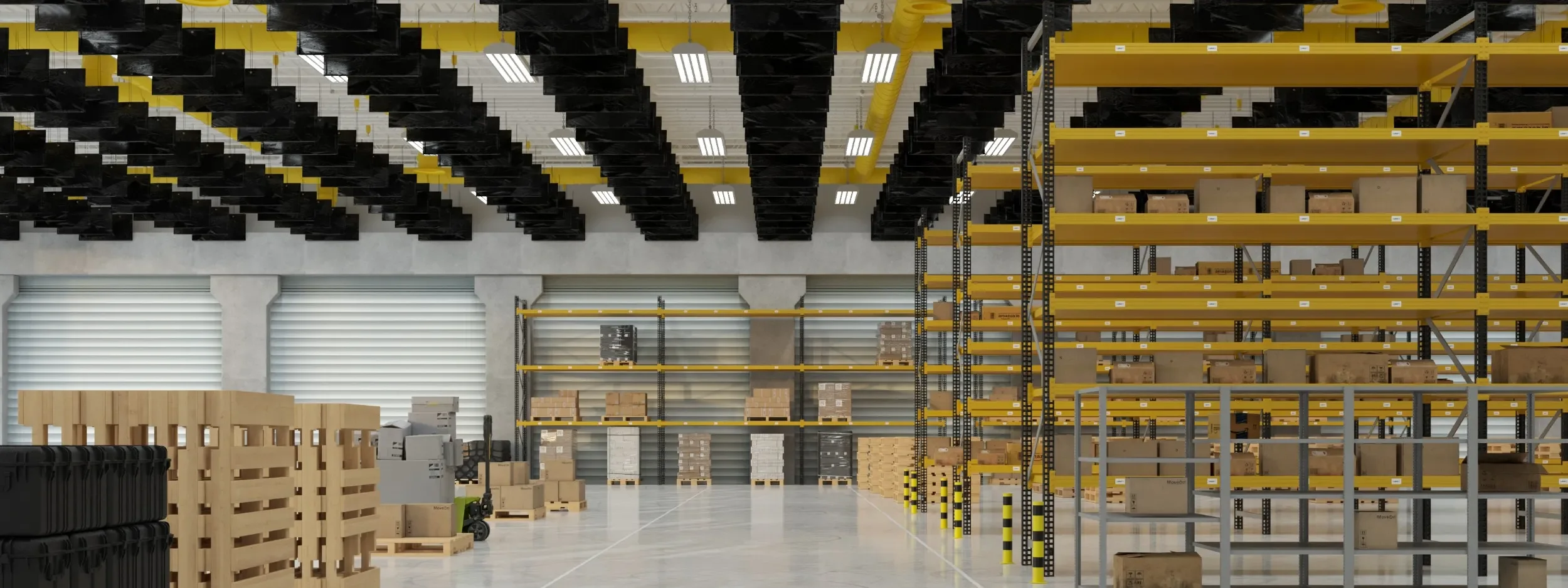

- Fulfillment Centers

Creating Quieter and More Efficient Fulfillment Centers with Effective Noise Control

Fulfillment centers operate at a fast pace, handling high volumes of goods, often accompanied by excessive noise from conveyor systems, forklifts, and other machinery. This noise can disrupt worker productivity, increase stress, and even pose risks to employee health and safety. Additionally, excessive noise can create compliance challenges with local and federal noise regulations. Implementing Fulfillment Center Noise Control and Soundproofing solutions is essential to creating a safer, more efficient, and comfortable workplace.

Our noise control strategies are tailored to the unique demands of fulfillment centers. From managing sound generated by conveyor belts and automated systems to reducing noise in breakrooms and administrative areas, our solutions address noise at its source and throughout the facility. Advanced soundproofing materials, acoustic barriers, and vibration-damping technologies are used to create a quieter environment that aligns with operational goals and safety standards.

By reducing noise levels, you protect employees, improve communication, and ensure smoother operations across all areas of the fulfillment center. Whether retrofitting an existing facility or incorporating soundproofing into a new design, we provide scalable solutions that enhance your operational efficiency and employee satisfaction.

Investing in fulfillment center noise control is a strategic decision that prioritizes employee well-being and operational excellence. Contact us today to learn how we can help you create a quieter, more efficient fulfillment center.

Reduces distractions, protects worker health, enhances communication, ensures safety compliance, lowers equipment stress, and boosts operational efficiency for a safer, quieter workplace.

Benefits of Fulfillment Center Noise Control

- Improved Employee Health

- Enhanced Safety Standards

- Increased Productivity

- Customizable Solutions

- Interior and Exterior Controls

- Enhanced Communication

- Lower Operational Costs

Most Often Used Products

Acoustic Noise Enclosures

Acoustic noise enclosures offer an effective, customizable solution for controlling sound emissions at the source.

Industrial Sound Baffles

In large, noisy industrial spaces, managing sound levels is crucial to improving communication, worker comfort, and safety. Excessive reverberation and noise buildup can make environments chaotic and lead to reduced productivity and hearing fatigue.

Metal Noise Barrier Walls

When powerful, low-frequency noise threatens the comfort, safety, or functionality of a space, traditional acoustic solutions often fall short.

Sound Barrier Composite Panels

In environments with high levels of noise, especially where both sound transmission and reverberation are problems, using a single type of acoustic treatment often falls short.

Frequently Asked Questions

A:

Noise control is crucial to protect worker health, enhance communication, improve productivity, and ensure compliance with noise regulations.

A:

Conveyor systems, forklifts, automated machinery, HVAC systems, alarms, and high-traffic areas are common sources of noise in fulfillment centers.

A:

Reducing noise exposure minimizes the risk of hearing damage and decreases stress levels, creating a healthier work environment.

A:

Soundproofing materials, acoustic panels, vibration-damping technologies, acoustic baffles, and noise barriers are highly effective for reducing noise and improving acoustic conditions.

A:

Yes, noise control measures can be integrated into existing facilities with minimal disruption to daily operations.

A:

Absolutely. Noise control strategies can be designed to adapt to facility expansions and increased operational demands. Generally, as spaces expand, additionally material may be necessary to accommodate a larger overall volume.

A:

By reducing noise levels to meet OSHA and other regulatory standards, fulfillment centers avoid penalties and maintain a safer work environment.