Integrated Absorption and Blocking for Advanced Noise Control

Sound barrier composite panels are acoustical systems that combine two core functions: blocking and absorbing sound. Traditional soundproofing typically involves either barriers, which block the transmission of noise, or absorbers, which noise buildup within a space. Composite panels combine both in a single solution, offering superior performance by addressing noise problems on multiple fronts.

These panels typically include a dense sound-blocking layer such as mass loaded vinyl (MLV), reinforced barrier materials, or perforated metal. Behind or sandwiched around this barrier is a layer of sound-absorbing material, usually fiberglass or acoustic foam. The result is a panel or curtain system that not only stops sound from passing through but also minimizes reflections and echo within the treated area.

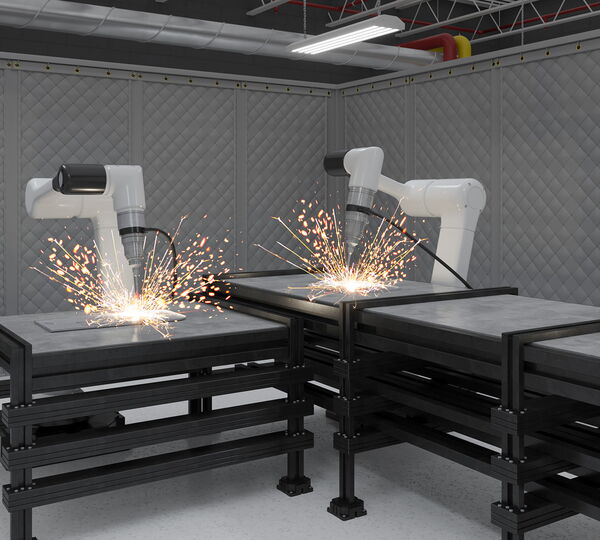

Composite panels can be constructed as flexible hanging curtains, modular wall systems, or enclosures, depending on the application.

Key Benefits of Sound Barrier Composite Panels

One of the main advantages of composite panels is their dual-action acoustic performance. The combination of absorber and barrier elements allows these panels to handle a wider frequency range and reduce overall noise more effectively than single-function products. Low-frequency machine rumble, mid-range voice or tool noise, and high-frequency hiss or echoes are all addressed simultaneously.

In addition to their acoustic properties, composite panels are incredibly versatile. They can be hung from overhead tracks as flexible curtains, mounted to frames or walls as semi-permanent partitions, or used to construct complete acoustic enclosures around noise sources. Their modular design means they can be rearranged or expanded as needed without extensive construction.

Composite panels are also durable and easy to maintain. Panels made from reinforced vinyl and quilted fiberglass are rugged enough for industrial environments, while perforated metal surfaces can withstand heavy use and offer a sleek, professional look in commercial or technical spaces. Many models are available with wipeable or cleanable surfaces, making them ideal for use in food production, labs, and healthcare settings.

Noise Barrier Composite Panel Products

Barrier Septum Panels

- Flexible panels with mass loaded vinyl sandwiched between two layers of quilted fiberglass absorber

- Used as hanging acoustical curtain, enclosure panel, or wall liner

- STC rating: Up to 33

- NRC rating: Up to .75

- Fire Rating: Class A per ASTM E-84

- Standard Panel Width: 48"

- Handles tough environmental conditions

- Standard Colors - Black, Tan, Gray, Off-white

- Designer Colors Available

Barrier Backed Curtain Panels

- Flexible panels with reinforced mass loaded on one side, quilted fiberglass absorber on the other

- Used as hanging acoustical curtain, enclosure panel, or wall liner

- STC rating: Up to 32

- NRC rating: Up to .85

- Fire Rating: Class A per ASTM E-84

- Standard Panel Width: 54"

- Handles tough environmental conditions

- Standard Colors - Black, Tan, Gray, Off-white

- Designer Colors Available

Designer Composite Curtain Panels

- Available as barrier septum or barrier backed panels

- STC rating: Up to 33

- NRC rating: Up to .65

- Standard Panel Width: 48", 54"

- Handles tough environmental conditions

- 12 Color Options

Metal Barrier Composite Panels

- Perforated metal panels for highest noise reduction

- Used in interior or exterior application where 25db+ reduction is needed

- STC rating: Up to 60

- NRC rating: Up to 1.04

- Fire Rating: Class A per ASTM E-84

- Handles tough environmental conditions

- Primed for Paint or Powder Coated

Frequently Asked Questions

A: Metal composite panels are rigid and typically mounted permanently to structures. They offer the highest available noise reduction, long-term durability and a sleek, finished appearance. Curtain composite panels, by contrast, are flexible and portable, often hung from ceiling tracks and used in areas where temporary or reconfigurable noise control may be needed. They are most commonly used when less than a 20db reduction is needed.

A: Composite panels are especially effective in industrial facilities, mechanical rooms, and any space where both sound transmission and internal reverberation need to be addressed. They are also great for server rooms, offices, and health care environments.

A: Many composite panels come with vinyl or coated finishes that are easy to wipe down or sanitize. Rigid panels with perforated metal surfaces are also highly durable and easy to clean, making them ideal for demanding environments.

A: Yes, DDS offers composite panels in a variety of sizes, thicknesses, colors, and mounting styles. We can also integrate custom features like doors, windows, and ventilation ports to meet the specific needs of your application.

A: Some composite panel systems, especially those with reinforced barriers and weather-resistant coatings, are suitable for outdoor use. DDS can recommend appropriate materials based on your location and exposure requirements.