Vibration Control For Reduced Impact and Structure Borne Noise

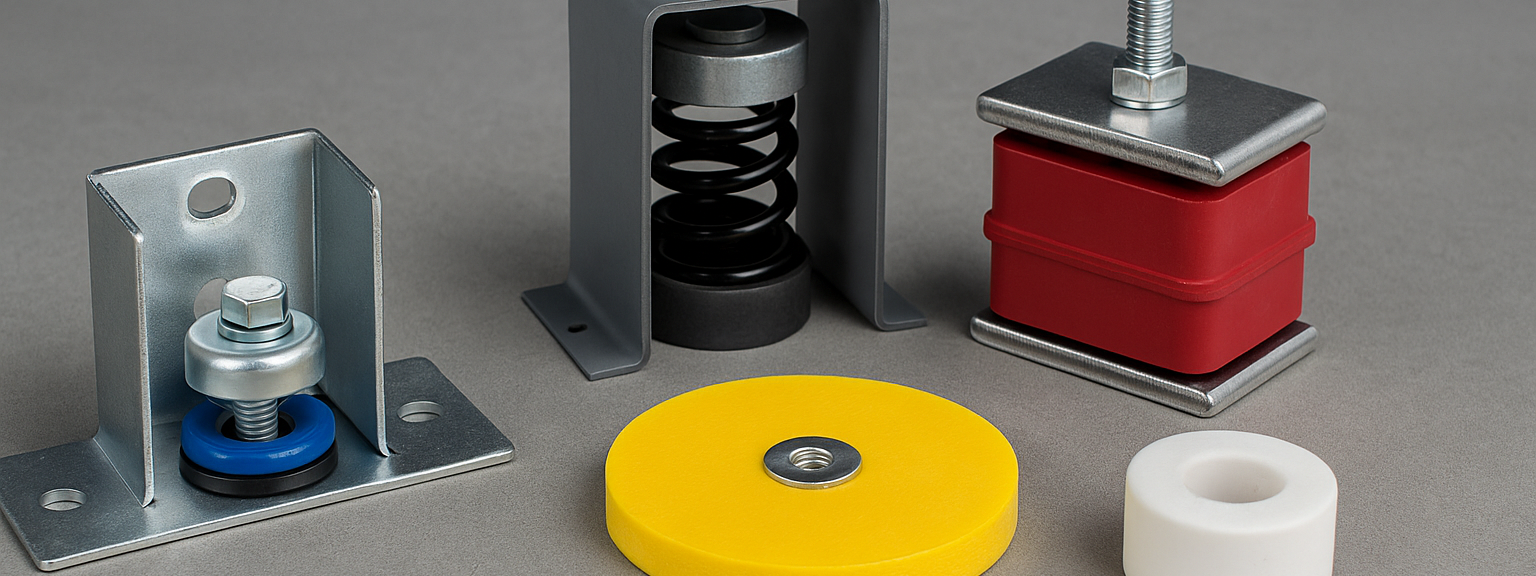

Vibration isolation products are specialized components that prevent mechanical vibrations from transferring through building structures. Rather than allowing machines or mounted surfaces to be in direct contact with the building’s framework, these products use spring, elastomeric, or rubber materials to “decouple” the source of vibration.

This decoupling helps to minimize the transmission of low-frequency vibrations into walls, floors, ceilings, and adjacent rooms—reducing structure-borne noise and preserving the acoustic performance of the space. Isolation solutions are commonly used in mechanical rooms, theaters, laboratories, gymnasiums, apartments, and multi-level commercial buildings.

Key Isolation Products and How They’re Used

Wall and Ceiling Clips Used in acoustic wall and ceiling assemblies, resilient clips isolate drywall or acoustical panels from the structure, minimizing the transfer of vibration and sound. They’re ideal for theaters, offices, conference rooms, and residential spaces requiring higher levels of sound isolation.

Vibration Isolation Hangers Suspended mechanical systems, piping, and ceiling assemblies often require vibration hangers with integrated springs or rubber elements. These devices isolate the suspended load from the structure above, preventing vibration from traveling through the ceiling or roof system.

Machine Pads and Spring Mounts For large HVAC units, pumps, compressors, and other heavy machinery, elastomeric pads or spring mounts provide the most effective vibration control. These products support the equipment while absorbing its dynamic movement. Spring mounts are especially useful for low-frequency applications and rooftop systems where vibration could travel through structural steel or concrete.

Floating Floors In environments like gyms, mechanical rooms, or performance spaces, floating floors with isolator mounts or pads prevent impact and vibration from being transmitted into the floor slab and adjacent rooms.

Benefits of Vibration Isolation

Reduces Structure-Borne Noise: Isolation prevents the transmission of vibration that becomes airborne sound, especially in low-frequency ranges difficult to manage with traditional acoustics.

Protects Building Structure: Minimizing vibration reduces wear on building connections and helps prevent cracking or fatigue in concrete, drywall, and steel systems.

Enhances Occupant Comfort: Quieter, vibration-free environments improve usability and experience for occupants in high-end residential, commercial, and institutional settings.

Improves Equipment Longevity: Isolated machines experience less vibration-related wear and tear, extending the life of HVAC, mechanical, and manufacturing systems.

Custom Engineering and Specification

At DDS Acoustical Specialties, we don’t believe in one-size-fits-all. Our team evaluates each project to determine the load conditions, required deflection, and vibration characteristics of your system. We then help specify the right combination of isolators, clips, mounts, or hangers to ensure peak acoustic and mechanical performance.

Whether you’re isolating a 10-ton rooftop chiller or designing a home theater ceiling to block footstep noise from above, we’ll provide detailed product data, design drawings, and coordination with your contractors or MEP engineers.

Frequently Asked Questions

A: Use vibration isolation any time mechanical systems or mounted assemblies are causing noise or structural vibration to travel into occupied or sensitive spaces. These vibrations can lead to noise disturbances, stress on the building structure, and discomfort for occupants. Common triggers include HVAC noise, gym equipment, heavy machinery, elevators, compressors, and even foot traffic in multi-story buildings. Vibration isolation is especially important in environments like hospitals, recording studios, libraries, and mixed-use residential buildings where even minor vibrations can lead to operational issues or complaints.

A: Installation varies based on the specific product and application. Wall clips are typically mounted to wall studs or ceiling joists, with hat channels or furring strips spanning between them to support drywall or acoustic panels. Hangers for piping or ductwork are suspended from above and include spring or rubber isolators to absorb vibration. Machine pads and spring mounts are placed directly beneath equipment during installation and must be carefully leveled and aligned. Accurate load distribution, proper anchoring, and secure fastening are critical for effective isolation. Our team provides detailed layout guidance and product specifications to assist installers and contractors.

A: Vibration isolation targets low-frequency structure-borne noise, which can be challenging to reduce with traditional soundproofing techniques. Depending on the type of isolator, load, and building construction, you can expect a reduction of 10 to 30 decibels or more. This can result in a significant improvement in perceived noise levels, particularly when isolators are used in tandem with complementary soundproofing materials such as ceiling panels, acoustic barriers, and sound absorptive treatments. Effective isolation not only reduces noise transmission but also improves room comfort and speech intelligibility.

A: Acoustical floor underlayments are often rated with an IIC (Impact Insulation Class) score, which quantifies how well a floor/ceiling assembly reduces impact sound transmission. A good underlayment can improve IIC scores by 10 to 25 points or more. Practically speaking, this equates to a noticeable reduction in footstep noise, dropped item echoes, and general floor vibrations. The level of improvement depends on a variety of factors including the existing floor assembly, the quality of the underlayment, and how it’s installed. It’s important to ensure underlayments are installed properly—gaps, overlaps, or using incompatible adhesives can compromise performance.

A: While small-scale or residential applications may not require formal engineering, we strongly advise consulting an acoustical or mechanical engineer for commercial, institutional, or code-sensitive projects. DDS Acoustical Specialties works alongside your engineering team or project consultants to ensure the solution is properly designed. We provide product data sheets, deflection calculations, and coordination assistance during submittal and construction phases to streamline implementation and compliance.

A: Yes. Retrofitting vibration isolation is a common request, particularly in adaptive reuse projects, historic renovations, or facility upgrades where mechanical noise has become a concern post-installation. Our product line includes low-profile and adjustable isolators that can be integrated into existing structures without requiring major reconstruction. We evaluate field conditions and recommend solutions that minimize disruption while maximizing acoustic improvement.

A: A wide range of mechanical and operational equipment can benefit from vibration isolation. These include rooftop air handling units, condensing units, chillers, cooling towers, emergency generators, press machines, milling or stamping equipment, and even cardio or weight equipment in gyms. Essentially, any machinery with motors, pumps, fans, or moving parts that can induce vibration through the building's structure should be considered for isolation to protect both performance and comfort.