Cadence Aerospace

The Tell Tool Division of Cadence Aerospace has a long and storied history of making precision parts for the aerospace industry. As they continue to grow and thrive, space becomes a premium. As the facility houses more and more activity, it was apparent that noise was going to become an issue. The machining process is not a quiet undertaking and supervisors at the facility knew that they needed separate the incredibly precise operations that were going on within the facility. Noise is vibration and vibration is the enemy of precise machining techniques.

Calling in DDS Acoustical Specialties, a solution consisting of Sound Seal’s BSC-25 barrier / absorber composite panels was recommended. Suspending roller track from existing structure would allow for “slide-by” access and keep the floor itself free from any hardware and impediments to process.

Recognizing the need for a complete solution, B-10R reinforced barrier was used as valance above the curtain panels to completely isolate the noise source from the other operations within the space. Full view windows were included in all panels to allow for visibility at the corners for safety purposes. A BBC 13 2” composite door was engineered into the enclosure to allow for ease of egress from the space.

Prior to the installation being complete, associates on the floor were commenting on the noise reduction. Once complete, depending on the type of material being run, the noise reduction ranged from 12-15 dB(A).Always cognizant of the ratio, “dB Per Dollar Spent”, this solution was accomplished without having to do any conventional construction, no permits needed pulled and the materials are all Class A per ASTM E-84 Flammability rated. Installed in the span of two days, all marveled at how quickly and easily the project was accomplished.

-

April 11, 2024

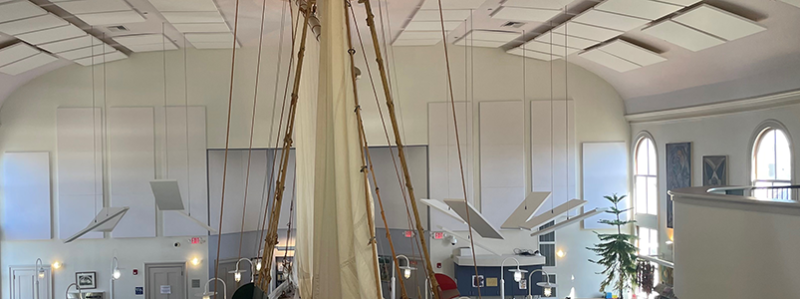

Acoustic Improvements at Provincetown Public Library

-

November 16, 2023

How to Soundproof a Room

-

September 26, 2023

Quieting the Racket: Understanding Pickleball Noise and Effective Solutions