Safe & Sound Week 2022 – Acoustics in the Workplace

In recognition of Safe & Sound Week, which takes place August 15-21 each year, we are going to discuss the importance of proper acoustics and noise protection in the workplace.

According to NIOSH, occupational hearing loss is the most common work-related injury in the US. Approximately 22 million US workers are exposed to hazardous noise levels at work. With proper hearing protection and noise control applications, we can reduce this number.

Safe & Sound Acoustics in Manufacturing

Many manufacturing and industrial workplaces are noisy spaces. It’s the nature of the business. When efficiency and productivity is key there ends up being lots of moving parts. Whether those parts are machines or people, they make noise that can be hazardous to employees.

According to OSHA, workers should not be exposed to noise levels of 85+dB over an eight hour period. Many precautions and applications can be implemented to ensure the safety of employees.

1. Acoustic Enclosures

The most common generator of noise in a workplace are machines. Stamp presses, CNCs, generators, saws, and air compressors are just a few examples. Loud machines sometimes run all day, increasing the danger to surrounding employees. To reduce the amount of noise workers experience from machines, we create an acoustic enclosure.

An acoustic enclosure is just as it sounds. It encloses a noise source on either all sides or partial sides. Enclosure can be full or partial, permanent, temporary, or portable. They are typically made of metal walls or curtain panel walls. Doors and windows are available additions to enclosures to allow access and viewing.

Full enclosures are also available with ventilation for machines that need airflow to control the temperature. Or a partial enclosure with no ceiling leaves ample room for airflow. However, an enclosure without a ceiling will allow noise to flank over and decrease the sound transmission loss of the system.

2. Sound Absorption

Another common source of noise in manufacturing is the everyday hustle and bustle. Sounds from communication, vehicles, moving objects, and so on. In an environment typically known to have reflective surfaces, all this airborne noise can build-up. Which is why it is important to introduce sound absorption to warehouses and factories.

There are many ways to add sound absorption to a space. However, you need to consider some key factors to make sure your absorption will work. One of the most important factors is room volume. Often times we see DIYers add a couple panels on a wall or ceiling but they still have an issue. This is the most common mistake we see. Without enough absorption and a properly calculated goal, it is difficult to get a desired result.

Products with high sound absorption properties include wall and ceiling panels, baffles, and curtains. All products are Class A Fire Rated and can be applied to ceilings or walls. In many industrial and manufacturing environments, we often recommend PVC baffles or acoustic curtains. These two products are affordable, effective, and extremely easy to maintain.

3. HVAC Silencers, Louvers, and Pipe/Duct Wrap

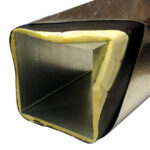

Many industrial and manufacturing facilities need to move lots of air to keep machines and the space cool. However, moving high amounts of air can also create high noise levels. This noise can be present both inside the facility as well as exiting. Exterior HVAC noise can create a nuisance for neighbors and the community. To create a safe and sound space and reduce noise from HVAC system we utilize acoustic silencers, louvers and pipe/duct wrap.

Custom designed and engineered, silencers and louvers reduce noise from HVAC systems of all sizes. They do their job by utilizing acoustical baffles as means for broadband sound attenuation in HVAC systems. All of our duct silencers are passive in design. They do not require mechanical or electrical means to function.

Additionally, acoustical pipe and duct wrap reduces the sound of air traveling through systems. Made with a mass loaded vinyl barrier, these products can also include a fiberglass absorber. The absorber serves as a decoupler and increases the performance of the wrap.

Safe & Sound Acoustics in Construction

Another source of noise and nuisance in communities is construction. Heavy vehicles and machinery making noise during all hours of the day or night can severely impact someone’s life. Whether it be watching television, sleeping, or working from home. There are acoustic applications that construction companies can take to ensure they are abiding by local noise ordinances and not disturbing nearby residents.

The most common application and product is Acoustic Curtains for fences. Acoustic curtains made of both quilted fiberglass absorber and sound barrier can be easily installed on chain link fences. Ideally, fencing with acoustic product should be 8ft high or twice the height and length of any noise source. They provide much needed noise reduction especially in residential areas.

Safe & Sound Acoustics in Commercial and Public Spaces

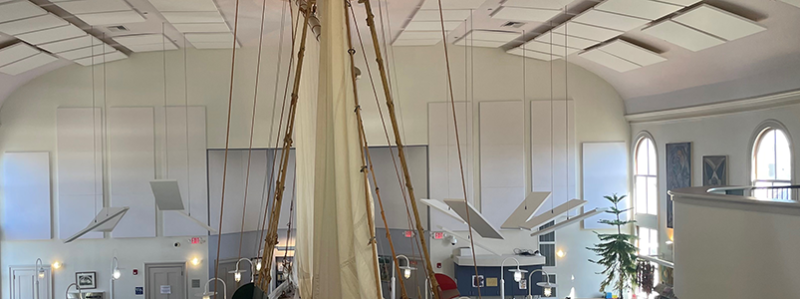

In addition to industrial and manufacturing environments, we also want to discuss some of the benefits of proper acoustics in other commercial spaces. Spaces such as bars, restaurants, offices, churches, libraries, and many more. In many cases, spaces with poor acoustics makes it difficult to comprehend spoken conversation, instructions, and other messages. This can create stress on a person’s ears and negatively impact mental health.

Thankfully there are solutions to improve the acoustic environment in commercial spaces.

1. Sound Absorption

We already touched on sound absorption earlier in this article. But when it comes to commercial and public spaces, it becomes even more important. Without enough absorption, noise builds-up and echoes. This causes poor speech intelligibility and creates an unpleasant environment.

For example – A bar/restaurant has a live rock band playing music. The space has no or little absorption in the space. This causes patrons to have to yell across their table just to have a conversations. With proper absorption, the band would still be able to play but the patrons would have an easier time talking with each other.

Acoustic absorption also serves as an excellent design piece for spaces. Products range from fabric wrapped panels, paintable panels, printed panels, foam, and felt, designed to meet any aesthetic need.

2. Noise Privacy

In spaces like doctor’s offices, conference rooms, and therapeutic practices, privacy is of the utmost importance. It makes clients and employees feel comfortable and at ease.

Privacy issues arise due to a number of factors. Main reasons typically include:

- Air gaps in doors, windows, and walls

- Lack of mass in walls/partitions

- Sound traveling through ventilation

Air gaps

The first thing anyone should do when trying to mitigate noise coming into a space is to search for air gaps. Sound is like water and will find any opening it can to get into a space. The most common air gap are those around door jams and bottoms. Proper acoustic sealing easily solves this problem. In addition, the heavier the door, the more sound it will block.

Ceilings

Drop or suspended ceilings may also create privacy issues. In some cases, the walls in a room do not reach the top of the ceiling decking. This creates an open air space that sound can travel between adjacent rooms. There are a couple solutions to this problem.

- Replace the existing ceiling tiles with Acoustical Ceiling Tiles with a noise barrier backing

- Install Noise Barrier Ceiling Tile Covers above existing ceiling tiles

Both of these options will solve the problem. For new ceilings the best route would be to use proper ceiling tiles with a noise barrier. For existing ceilings with tiles already installed, spaces can save money by using noise barrier ceiling tile covers.

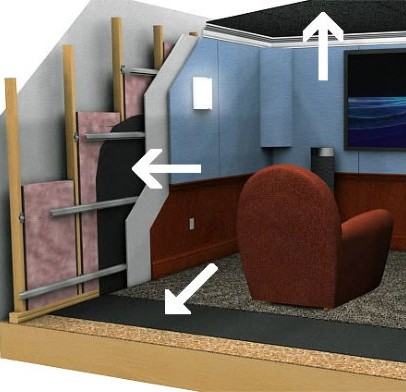

Walls

When it comes to walls as sound barriers, the main principle to know is more mass = higher Sound Transmission Class (STC) and known as the mass law. For example, concrete block stops more sound than drywall because it has more mass. In many residential and commercial applications, customers will reinforce their drywall with a mass loaded vinyl barrier (MLV). MLV is a flexible product that weights 1 or 2lbs per square foot. This means that the additional mass behind drywall with significantly improve its STC rating and stop more sound.

However, there are ways to cheat the mass law such as:

- Decoupling partitions

- Adding Mass of varying thicknesses

- Staggering studs for an additional air gap between

Safe and Sound – In Conclusion

Our goal at DDS Acoustical Specialties is to create a better, safer sounding world for our customers. We hope this article touched on some of the common noise issues in industrial, manufacturing, construction, and other commercial applications. If there is a noise problem, we are happy to help solve it!

-

April 11, 2024

Acoustic Improvements at Provincetown Public Library

-

November 16, 2023

How to Soundproof a Room

-

September 26, 2023

Quieting the Racket: Understanding Pickleball Noise and Effective Solutions